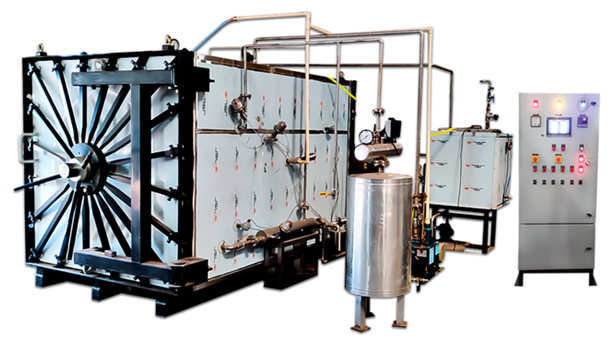

Fully Automatic ETO Sterilization Chamber

Brief Introduction:

Ethylene Oxide Sterilizer is the special equipment, sterilizing the things in the cabinet with ethylene oxide gas. It precedes low-temperature fumigation sterilization in the given terms of temperature, pressure and humidity. The equipment is widely used in the medical industry.

Advantages:

- Automatic cycle progression is feasible in ETO Sterilizer through vacuum, exposure, sterilizing, and aerating phases

- The control panel screen indicates specific phases in the sterilization process

- Negative pressure of chamber prevents the gas from entering into operating area.

- Strict control of vacuum, temperature of chamber, exposure (aeration time) etc. for effective performance.

- A leak test function eliminates any leakage possibility in ETO sterilizer

- Chamber and cabinet made of the finest quality stainless steel

- Aeration system safeguards the operator from exposure to EO gas

- Easy & efficient operation

- Printer for recording process parameters

- Touch screen HMI for easy operation

Main Technical Parameters:

| Chamber Capacity: | 5CBM and 10CBM (Customizable) |

| Temperature Sensor: | 0-300˚C |

| RH Sensor: | 0-100% RH |

| Pressure Sensor: | -1 to 3 bar |

| Air Pressure: | Min. 6 bar |

| Overall dimension: | (L×W×H) 1200*1000*1300mm |